|

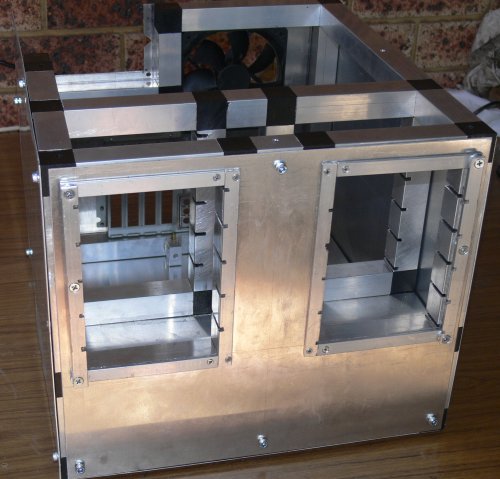

Well the case is almost

done. Came across a few little hickups. The main one being

when I initially measured the motherboard I got 300mm and it

is actually 305. The problem is I got all the panels pre-cut.

Doh. If anyone has some ideas on how to cover the gaps then it

would be much appreciated.

At this stage I have it

running with two old disks, switches hanging out the side and

a USB stick in the back. I have proper switches on the way and

also have some new fans, fans controllers and grills ordered

as well. Note it is running Freenas, runs completely off a USB

stick.

Here you see the front all done. The frame

provides a clean edge and also is the latching mechanism for

the drives craddles

Here you see the drives fitted. Looks nice

and tidy and clean. Notice the gaps, any tips for fixing,

covering or replacing would be much appreciated.

Here's a shot from the back showing Fans,

drives and MB face.

With the low flow silenx fan in place it is

still quiet and still easily flows enough to keep the drives

cool.

Basically all thats left is to fix the gaps

around the edge, Bling it, install a lian li smart fan

controller and polish the aluminum plate. Its all works as

expected. Nice and quiet and keeps the drives cool.

To

fit

|